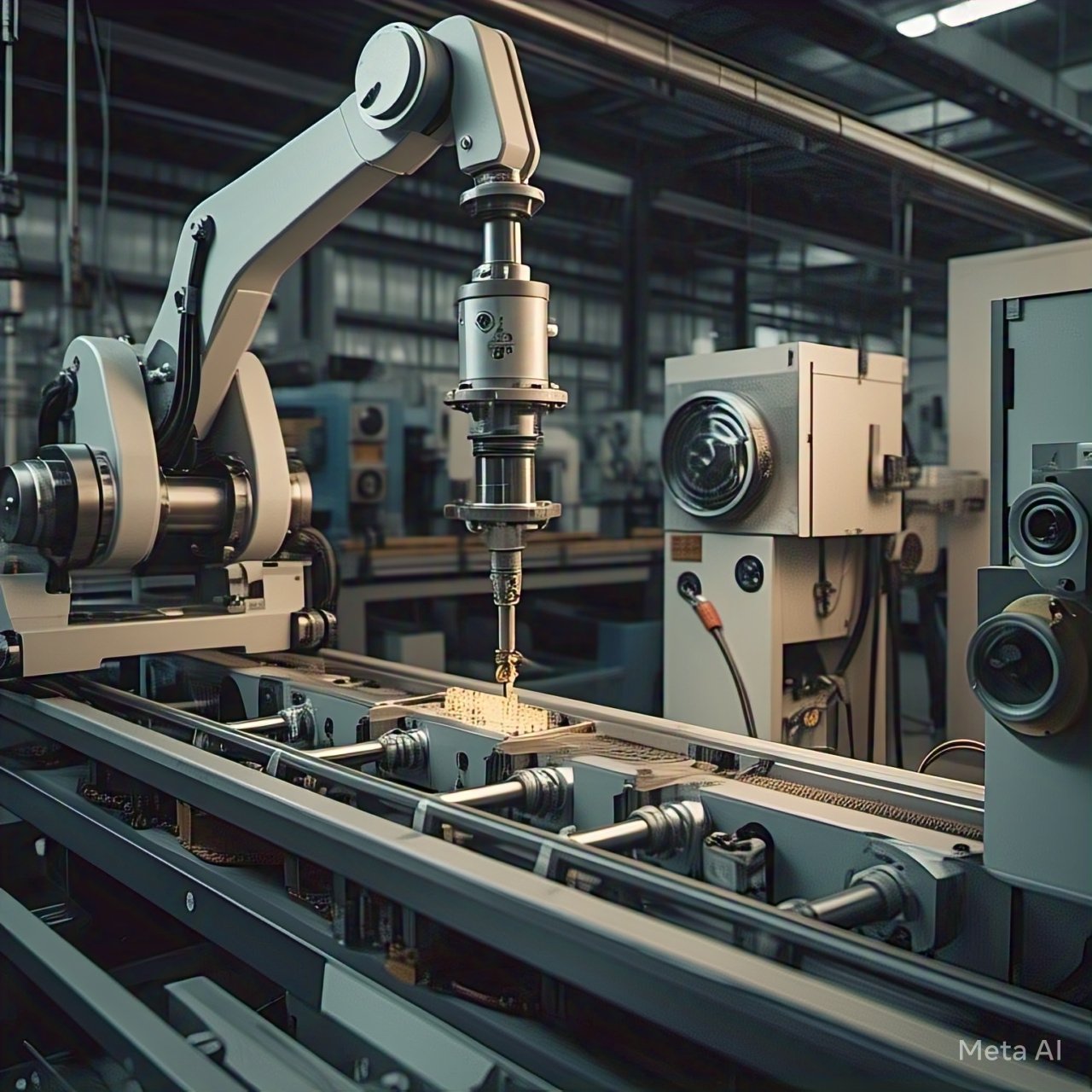

Automation processes across different industries depend heavily on hydraulic cylinder mechanisms. Their reliable force delivery system increases manufacturing precision. And industrial automation performance while improving production efficiency for robotics. The paper examines hydraulic cylinder usage within automation. While examining its impact on production efficiency together with accuracy levels.

1. Role of Hydraulic Cylinders in Automation

Hydraulic cylinders use hydraulic energy to produce mechanical force. Which gives automated systems accurate maneuverability control. Hydraulic cylinders serve the automotive, construction industries, aerospace, and packaging divisions. Because these fields need precise and strong operating mechanisms. The automation world benefits from hydraulic cylinders. Due to their strength during heavy load handling. And their capability to generate steady movements. The technology provides businesses with a cheap approach. To operate powerful motion control systems for extended periods.

2. The main applications of hydraulic cylinders power automated systems

a. Industrial Manufacturing

- Hydraulic cylinders serve as essential components for automated assembly operations. Because they execute heavy component movement functions including lifting and precise positioning tasks.

- The robots rely on hydraulic cylinders to execute exact small-scale product processing actions. Which includes cutting welding and stamping.

- Press machines depend on hydraulic cylinders to produce effective material forming. And bending while also conducting material compression operations.

- The quality output of manufacturing operations remains steady. Through steady hydraulic pressure applications in manufacturing equipment, read now.

b. Robotics and Material Handling

- The implementation of robotic automation depends on hydraulic cylinders. to deliver massive forces required for material lifting activities and item gripping needs.

- The systems enjoy hydraulic cylinders to execute control. And exact product movement through conveyors.

- Smooth vertical movements operate on automated forklifts. And lifting platforms through hydraulic cylinders for controlled operation.

- Hydraulic robotic arms found in warehouse operations perform efficient product sorting. And packaging operations.

c. Automotive and Aerospace Industry

- Automated vehicle assembly requires hydraulic cylinders as an essential component. Mainly for pressing and forming plant elements.

- Such devices operate in painting and coating applications to deliver motion. That remains smooth while also achieving even distribution.

- High-precision machining alongside testing procedures in aerospace manufacturing depends on hydraulic actuators.

- Hydraulic systems operating in plane landing gear and flight control systems provide greater stability together with safety benefits.

d. Packaging and Food Processing

- Hydraulic cylinders serve three main functions within automated packaging machines. Where they carry out sealing operations. And cut operations as well as perform labeling tasks.

- Hydraulic cylinders deliver exact positioning requirements in machines. That applies to fill quantities and place caps.

- The automated hygienic control of processed food products results from hydraulic automation systems.

- Fast hydraulic presses enable fast packaging at high speeds. Through their capability to maintain product quality which shortens production stoppages.

3. Benefits of Hydraulic Cylinders in Automation

a. High Power and Load Capacity

- The ability of hydraulic cylinders to deliver large powered motions. It enables their perfect implementation in demanding industrial operations.

- The devices produce a steady function. When handling heavy loads together with high-pressure conditions.

- The force output from hydraulic systems equals that of mechanical alternatives. But they provide these outputs through smaller packages and lighter systems.

b. Precision and Control

- High-accuracy automation happens through movement control. It results from the combination of sensors with servo technology. Within advanced hydraulic systems.

- The ability to adjust pressure along with flow rates establishes precise operation.

- The ability of hydraulic actuators to control force output makes them ideal for analytical automation work.

c. Durability and Reliability

- Production machinery employs hydraulic cylinders which show resistance to damaging industrial conditions.

- Sealing technology properly applied creates leak-proof locking mechanisms. Which leads to extended operational durability.

- Hydraulic components get longer operational lives. It happens through the application of both corrosion-resistant coatings along wear-resistant materials.

d. Energy Efficiency and Cost Savings

- The present hydraulic systems maximize energy performance. It occurs by controlling both system pressure and fluid movement rates.

- Better maintenance requirements result in decreased operational costs. Which leads to higher machine availability.

- The adoption of variable displacement pumps within hydraulic pump technology enhances the system’s performance efficiency.

4. Future Trends in Hydraulic Automation

- The integration of AI technology with IoT facilitates the use of real-time data. For hydraulic system predictive maintenance and enhanced performance optimization.

- Separate electricity and hydraulic systems merge through electro-hydraulic setups. This is crucial to enhance operational precision and efficiency.

- An eco-friendly approach to hydraulics consists of deploying biodegradable hydraulic fluids. Together with energy-saving technologies reduce the environmental footprint.

- The implementation of smart monitoring systems utilizes new sensors. That spot hydraulic leaks and performance issues during their initial stages of development.

Conclusion

Hydraulic cylinders are very important components in the automation industry. It enables precise, accurate, and high-force operations. They have the creativity to improve production speed, accuracy, and reliability. They are considered indispensable methods in modern manufacturing and robotics. Investing in high-quality hydraulic solutions makes sure that long-term savings are achieved. Along with improved operational efficiency and enhanced product quality.